Case Studies

Eliminating High Frequency Pulsation and Vibration from a Screw Compressor

Challenge

As part of the vapor recovery system in a refinery, a two-stage screw compressor was used to boost gas pressure prior to burning the gas in plant boilers. This VRU compressor experienced numerous vibration-induced failures of the auxiliary piping as well as excessive vibration of the main piping and high noise levels in the vicinity. The vibration and noise were reported to vary from day to day.

Our Process

To investigate the problems, EDI employed multiple insertion probe dynamic pressure transducers, vibration sensors, strain sensors, and microphones to monitor the data for a period of one week. Process data including gas composition, pressures, and temperatures were also obtained to correlate with the measured vibration, pulsation, and noise.

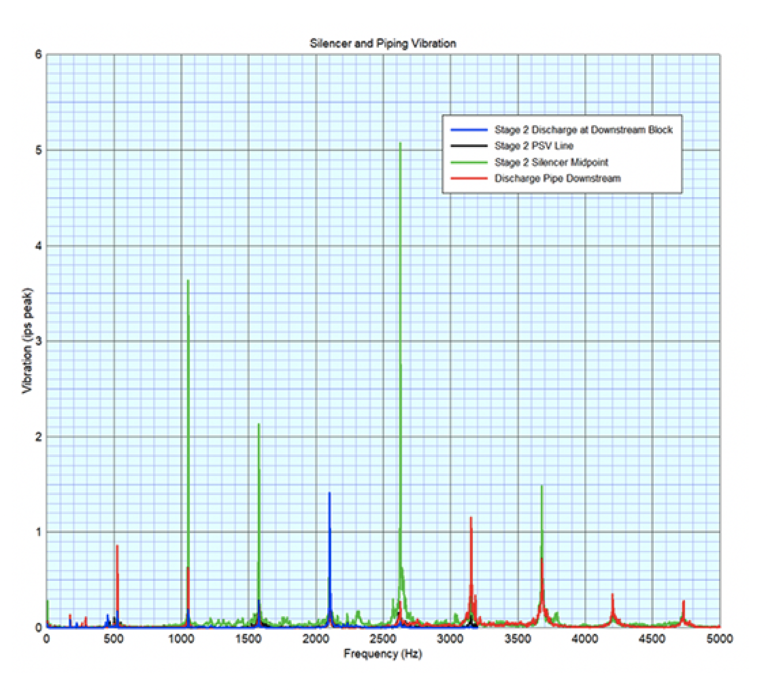

The data showed that the vibration and noise was predominated by high order multiples of “pocket-passing frequency” (PPF). Vibration amplitudes as high as 5 ips 0p (130 mm/s) were recorded. Vibration and noise were associated primarily with the 2nd stage discharge silencer. Monitoring showed that variations in the severity of vibration and noise coincided with speed of sound changes of the gas due to changes in process conditions.

Based on the data, it was hypothesized that there were acoustical or mechanical natural frequencies that amplified PPF pulsation energy. Calculations showed that coincidences of shell-wall mechanical natural frequencies and cross-wall acoustical natural frequencies of the silencer could coincide with PPF multiples, depending on process conditions. It was therefore decided to replace the 2nd stage silencer.

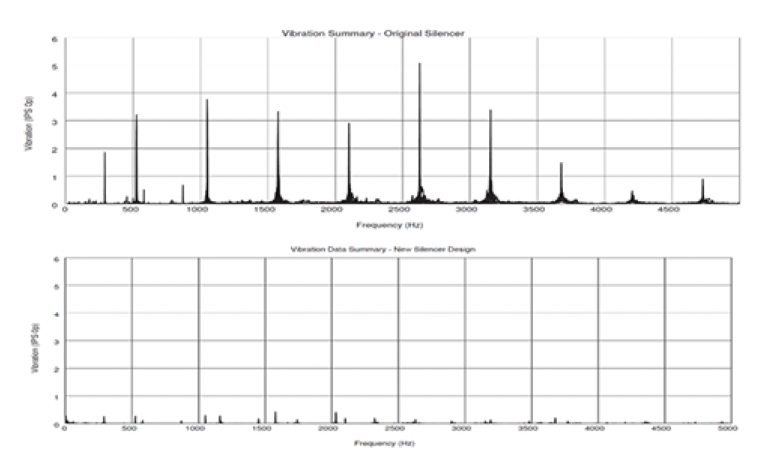

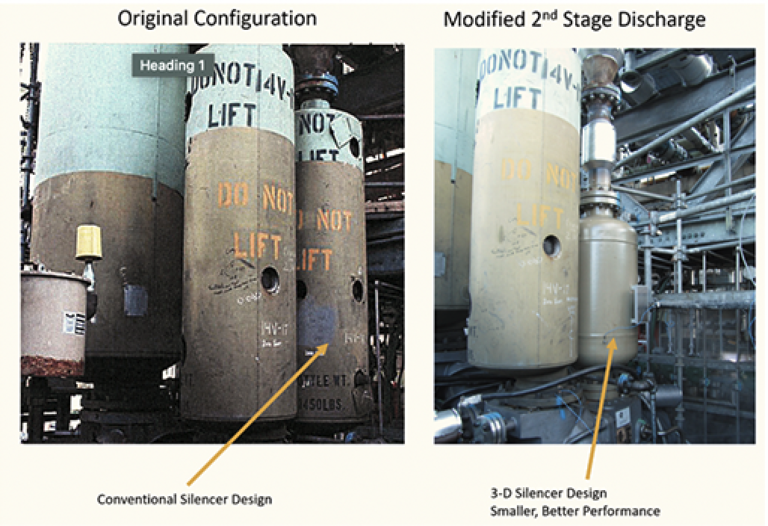

The existing “silencer” was a conventional design consisting of a large volume with an internal baffle and choke to provide a low-pass acoustical filter. These designs are intended to attenuate PPF pulsation and higher. However, the designs are based on 1-dimensional acoustics and ignore the effects of high-order acoustical natural frequencies. Combined with the mechanical shell wall natural frequencies, amplification of higher PPF multiples occurs, as is shown in the spectra above.

Solution

A 3-dimensional silencer was designed for this application. Because of the nature of the gas, the silencer had to be a reactive design only (i.e., no absorptive material could be used). In this case, the new design was smaller than the original, so it fit easily in the space available. Pressure drop through this silencer was similar to the original design – 1-1.5% of line pressure.

Results

After installation of the new silencer, the VRU was returned to service. It was immediately obvious that noise levels radiating from the piping were greatly reduced. The vibration survey that had been done previously was repeated, and a before/after comparison was made, as shown in the summary plots below. Note that all datapoints for a particular survey are overlaid to show maximum values without regard to the specific location.